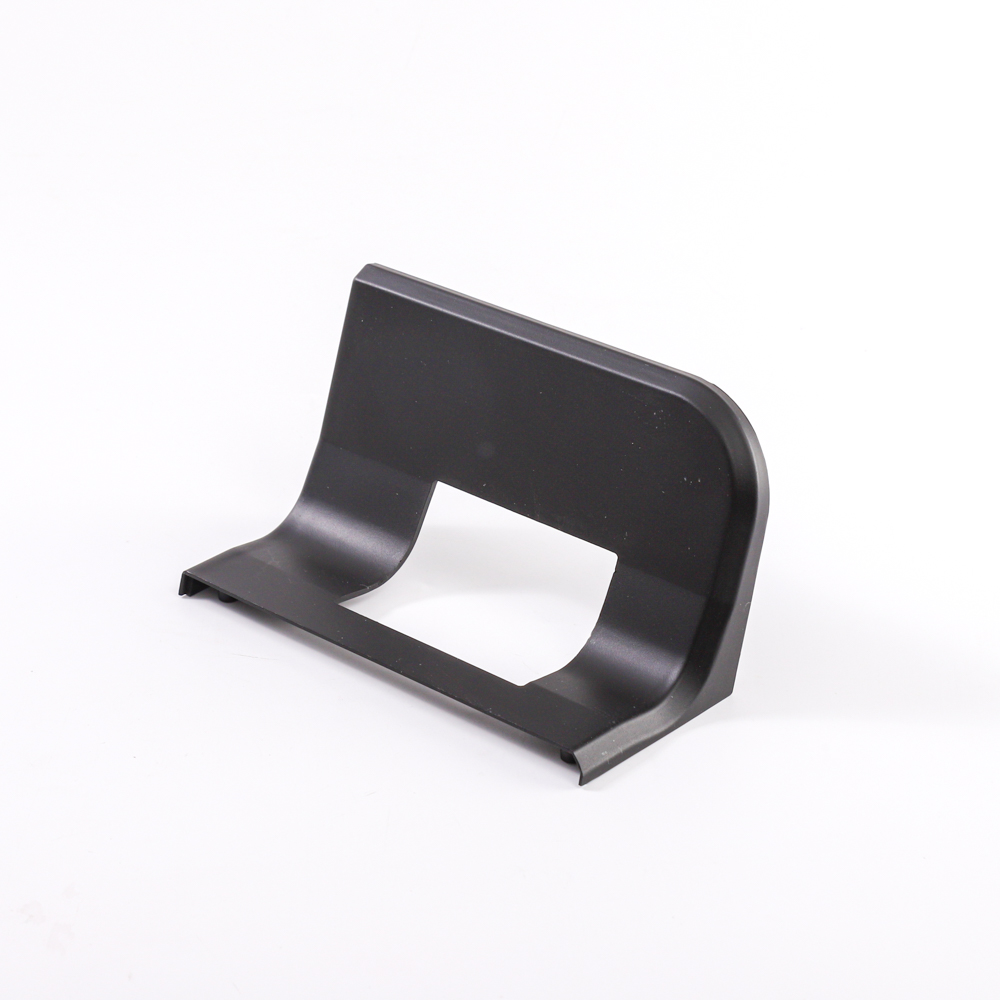

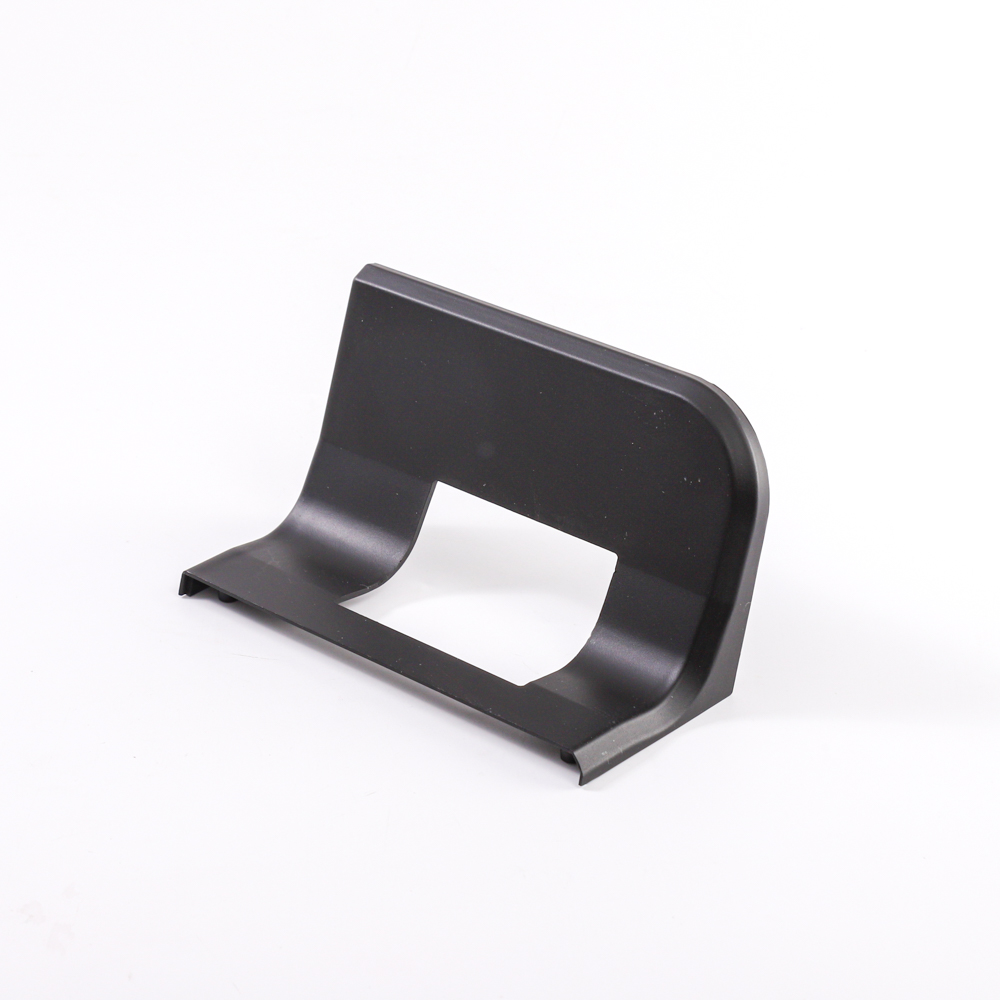

There are many kinds of Plastic Injection Components, customized drawings, factory direct sales prices are more favorable, various material specifications are complete, from design to processing, we have all-inclusive, professional customer service, and provide you with the best solution.we will quickly quote you, the customer confirms the quotation and places an order, the product processing is completed and the packaging logistics is arranged, and the customer confirms the receipt Goods praise. Plastic Injection Insert Molding is versatile and durable, we only make high-quality Plastic Parts.

Plastic mold casting systems can be divided into three categories according to different types of molds:

(1) Door mold, gate and gate parting line, mold and peeling, the most simple design, convenient processing, and low cost, so more and more people use the door system to operate.

(2) Nozzle mold: The gate and gate line are not divided into types. Usually, a set of nozzle parting line is designed directly in the product design. The design is more complicated and the processing is difficult. The fine nozzle system is often selected according to the product requirements.

(3) Hot runner mold, the mold is the same structure and fine nozzle, the biggest difference is that one or more heat flow, temperature and hot pumping nozzle, but not cold feeding and demoulding, the runner and gate are directly on the product, So the port does not need demoulding, also known as pouring system, this system can save raw materials, suitable for products with expensive raw materials, high demand, difficult mold design and processing, and high cost. The heat flow channel system, also known as the heat flow channel system, is mainly composed of a heat flow channel cover, a heat flow channel plate and a temperature control electrical box. There are two commonly used heat flow channel systems: single-point heat flow channels and multi-point heat flow channels. Using a single-point thermal gate, the molten plastic is injected directly into the cavity with a single thermal gate sleeve. Multi-point hot sprue is used to branch molten material into each hot sprue sleeve and then through the hot sprue plate into the mold cavity